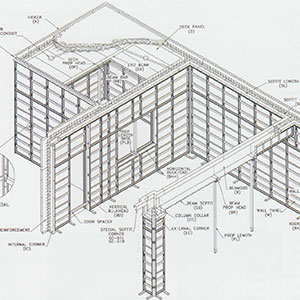

MFE Formwork Technology Sdn. Bhd Malaysia Aluminium Formwork

MFE Formwork Technology is a revolutionary aluminium formwork construction system, which has been successfully used and developed over 20 years, for forming cast in place reinforced concrete building structures. Using this unique system, all walls, floor slabs, columns, beams, stairs, balconies, together with door and window openings are cast in place in a single site based operation. The resulting building structure is very strong, accurate in dimensions and tolerances, with a high quality of finished concrete surface and yet at the same time the MFE Formwork Technology is fast, adaptable and very cost effective.

MFE was first formed in 1991 and has worked in over 16 countries throughout the region and are currently working in India, Singapore, Dubai, Malaysia, Hong Kong, Abu Dhabi, Thailand, Romania, Oman, Sri Lanka, Egypt and Libya. MFE has offices in Malaysia, India and Dubai.In Sri Lanka, We have supplied MFE Formwork for more than 10 projects and all the leading contractors/developers in Sri Lanka have used MFE Aluminium System Formwork for their projects.

Alsina Formwork Solutions

Alsina is the biggest provider and manufacturer of formwork and scaffolding systems in the world. They continue to grow through the large-scale expansion of the production facilities at the main production plant in Barcelona, Spain. Alsina has set the course for the future. Large, world-wide combined numbers of units lead to favourable manufacturing costs and reliable quality due to a high level of automation.

Efficient production processes, strict checks carried out by official institutes along with the technical expertise of the best-trained workforce leads to high quality standards of Alsina steel, wood and aluminium system equipment.

With its technical expertise based on decades of experience, Alsina is your competent partner regarding choice, planning and supply of plywood and formwork systems including all details such as surface structure, edges, joints and ties.

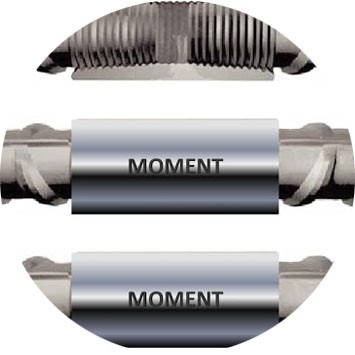

Halfen MomentMechanical Couplers and Bar Connectors

The Halfen-Moment Group of companies started its business in Malaysia, supplying mechanical couplers to the building sites by as a cost effective alternative for conventional splicing. Today the MOMENT™ coupler is a well established brand in the market . The successful cooperation with our customers motivates us to continuously extend our product offering to more reinforcement and construction accessories.

The Halfen-Moment Group of companies is present internationally via its own entities, affiliate companies and committed distributors.

With the headquarters in Malaysia, which serves as the central hub, and being supported by its subsidiaries in Singapore, Philippines and India, we have positioned ourselves as a leading building products player with an established and extensive network throughout Asia and Europe.

Halfen (A CRH Group Company) Cast-In Channels and Lifting Gears

With over 1,100 employees in 15 countries and more than 20,000 products HALFEN is one of the most successful concrete anchoring, façade fixing systems suppliers in the world. We offer our customers the highest quality products for building pre-cast concrete elements, commercial and residential construction, as well as civil engineering and for transport and infrastructure buildings. Our brands including "HALFEN", "DEHA", "DEMU" and "FRIMEDA" are among the market leaders. We want to maintain this position and grow it internationally.

Since the company was founded in 1929, our aim has been to provide bespoke, innovative and cost-effective solutions. We do this with passion and competence, along with the highest levels in technology, quality and safety. HALFEN innovations have been, and continue to be revolutionary for the whole industry. In the future too, we want to play a part in shaping progress. That is why we invest in research and development.

The high demands we set ourselves are also reflected in our relationships with employees, customers and suppliers: our dealings at all levels are characterised by trust, respect and reliability. We are looking for long-term international growth, and we will only achieve that by consistent costmanagement, professional operation and not least by confirming the trust placed in us and our products.

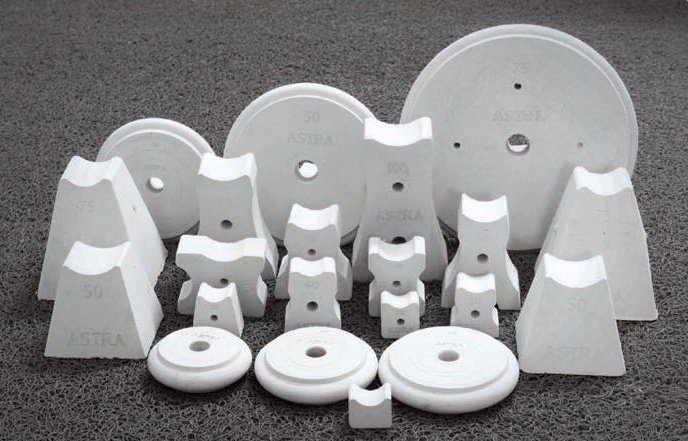

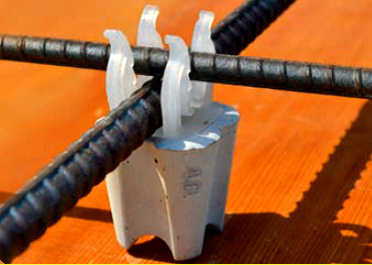

Astra SpacersAstra Concrete

ASTRA Concrete Products is the pioneer in introducing concrete spacers (cover blocks).

Over the years ASTRA has become benchmark of high quality in fibre concrete spacers.With multiple tests conducted at reputed domestic and international test labs, ASTRA spacers have been approved and used in various prestigious projects.

Astra Concrete Spacers are made under strict quality control with compressive strength not less than 60 MPa. Astra Concrete Spacers do not deform in heat, cold or under weight. Astra Spacers have a low permeability; tests on our spacers also indicate a low water and chloride ion penetration.

ASTRA spacers are used in hundreds of projects in New Zealand, Japan, Vietnam, Sri Lanka, Kuwait, Qatar, U.A.E., India, Saudi Arabia and Malta. We are an ISO 9001:2008 Certified Company.

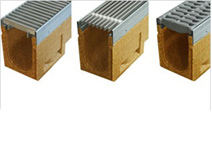

ANRIN Drainage System

At our production and logistics centre located in Anröchte, North Rhine Westphalia, ANRIN have been developing and producing pioneering drainage systems made of resin concrete and cover gratings for all physical and artistic demands of modern drainage around your house, yard and garden since 1971.

They are able to supply any construction site in Germany in less than 48 hours as well as many other countries within just a few days. Always new, creative and patented channel and grating systems give our demanding construction managers, architects, tradesmen and specialist dealers the safe and secure feeling that they have made the right choice for the long term.

Millions of metres of installed channel and certification in accordance with DIN EN ISO 9001 assure the high quality of our owner-operated family company. We place a special emphasis on technical and application-based consultation, with the goal of continuously finding the best solution for your individual construction project.

Amtek Mould Oil

AMTEK Mould Oil is a low cost, highly effective release agent for metal, plastic, wood and composition formworks. It is a blend of natural organic chemicals which impart a waterproof film to prevent adhesion of concrete to the forms and provide for quick and easy release.

AMTEK Mould Oil is supplied ready to use as a thin, milky white coloured liquid of low viscosity.